Heat treatments are an excellent and proven method for effectively eliminating a bed bug issue. However, there are potential pitfalls to the method, with one of the most common being damage to materials in the space. This is especially concerning whether you have your own pest control business or manage property like apartment buildings or hotels. Most bed bug heat treatments have operating space conditions of 120 degrees to 150 degrees Fahrenheit. There are a host of items susceptible to these high temperatures, from wax candles to vinyl blinds. We will cover some simple methods and best practices to avoid damage from heat treatments.

Thermostatic Controls

When using heaters to eliminate bed bugs, the operator should use equipment with thermostats to maintain a safe operating temperature. Our preference for our clients is to not exceed 140 degrees F. A very high percentage of materials will hold up well to these conditions, but risk climbs exponentially as temperatures climb above 140F. Our heaters such as the Sleeptight 800 and all of our electric heaters have built-in max temperature setting of 140 degrees F. Building supplies that are utilized in modern construction have become thinner, lighter weight, and have incorporated blends of different raw materials. For example, wood and plastic have been combined to generate goods such deck materials, blinds for windows, flooring, and many other supplies. Wood holds up well to extreme temperatures, whereas thinner plastics are susceptible at a much lower temperature. Lack of thermostatic control with your heat can result in excessive temperatures because the technician performing the work can become distracted, interrupted, or the heater may be oversized for the space. Without a safeguard to shut the heater on and off once it achieves desired space temperature, the structure has increased risk for damage.

When in Doubt, Protect It

If you are unsure of a material’s ability to handle the temperature, find a way to protect it to help avoid damage from heat treatments. For instance, vinyl plank floors are a material that has gained popularity in new construction. Depending on the manufacturer, the material thickness may vary as well as the maximum heat exposure temperature. We recommend placing moving blankets over the floors where the heat source is, and where the high-temp circulation fans are distributing air. This will give more of a time buffer to assess the floor’s “reaction” to heat, as well as more time to let the material to acclimate to the heat. As the treatment progresses, the technician can slowly start to remove the blankets to ensure all areas achieve the “kill” temperatures. The same principle applies to Thermofoil kitchen cabinets, pianos, grandfather clocks, etc. You can take it a step further and contact the manufacturer if you are unable to obtain material temperature ratings online.

Acclimation

We mentioned acclimation in the previous paragraph. Acclimation in heat treatments is raising the temperatures in slower controlled fashion to give the material time to adjust to the new environment. It’s a similar approach used in the installation of flooring such as wood planks. Installers will normally leave the materials in box for 48 hours in the installation space to give the material time to adjust to the humidity and temperature of the space to avoid gaps from expansion/contraction. By no means are we saying to heat for 48 hours, we are simply recommending raising the space temperature in 10 degree increments once 100 degrees F is reached. You can set the thermostat on your heater to 100F, then 110F, then 120F, and so forth. This provides the sensitive material time to adjust, and the technician time to inspect the materials for potential damage. This is especially useful for multi-piece shower surrounds, laminate floors, blinds, and vinyl floors.

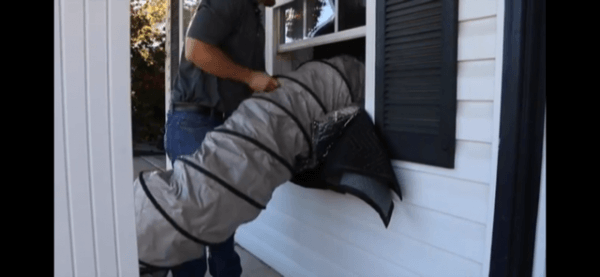

Gas-Fired Systems

Gas-fired systems are excellent for heat treatments because of the heat capacity that can be produced by one single unit; allowing the operator to arrive at “kill” temps very quickly. However, there must be precautions taken to prevent the source from causing damage, especially forced-air systems. Temperatures as high as 275 degrees F may be coming out of the end of the duct. While this sounds scary, the heated air is quickly blended with the use of proper airflow. Always wrap the duct with Reflectix insulation and a moving blanket at the transitions of vinyl windows where the duct is introduced, and a blanket or more insulation at the end of the duct where the heated air is being discharged.

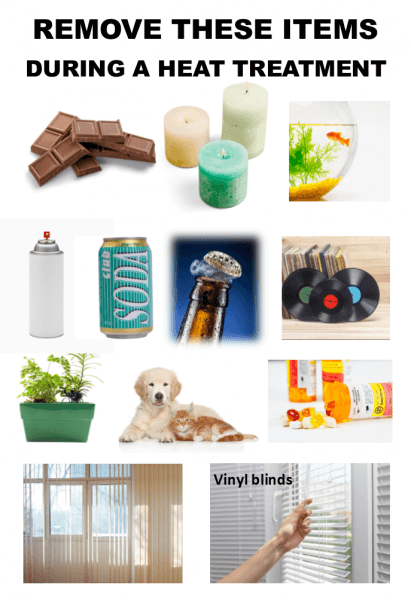

Preparation

Another strategy to avoid damage from heat treatments is preparation. Proper preparation is crucial to safely perform heat treatments and is arguably the most important step. Removal of pressurized cylinders, candles, chocolates, oil paintings, and medications should always be practiced. Vinyl blinds should be drawn up, removed from the frame, and placed on the floor. Failure to do so can result in a small mess to potentially serious injuries. As an example, aerosol cans will burst in heat treatments disbursing pieces of metal at very high velocities, which is why it is paramount to thoroughly inspect the structure at the beginning of the treatment.

While this is not an exhaustive guide for avoiding damage, it covers a lot of common issues that treatment professionals encounter on a daily basis. If you are searching for a safe, thermostatically controlled bed bug heater that would be suitable for your needs, please consult with a Thermal Flow Technologies representative by calling 833-401-3569 extension 1, or send an email to [email protected].