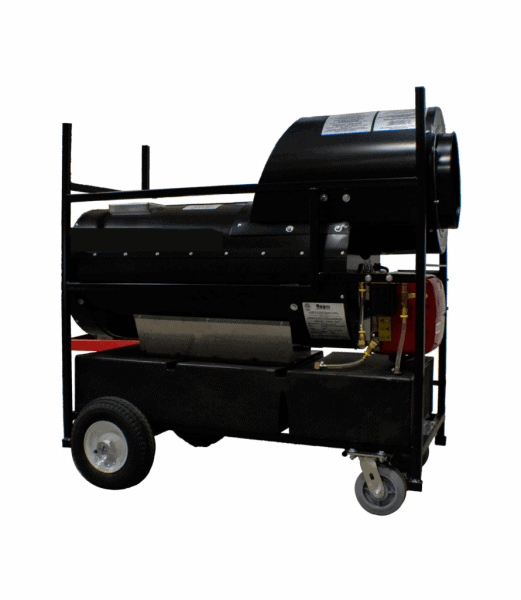

There are 3 important elements involved in monitoring the heat drying process. They are as follows: Proper meters and their calibration, where to take readings, and how you interpret them. Without all 3 components, drying efficiently and effectively will become a challenge. Each one of these will be explored in-depth. Different types of measurements will be taken based on what heat drying equipment you’re using; from diesel indirect-fired heaters, forced-air propane heaters, or electric heat drying systems.

Penetrating Meters- When using a penetrating meter, moisture content readings can be skewed upwards and give false “wet readings” at higher temperatures. Penetrating meters typically come with a manual, or the manufacturer has a handout to calibrate or adjust your moisture contents based on the temperature of the material. Other meters like the Delmhorst Navigator Pro have the ability to adjust for temperature and wood types. This is important to prevent potential drying materials below their EMC threshold and causing damage, and/or drying 1-2 days extra resulting in unnecessary cost and expense to all parties involved.

Non-penetrating meters– are still needed, great for quick scanning, drywall, use for wood floors 1” thickness or less.

Thermal cameras give an excellent visual to monitor the effectiveness of your drying setup. Early in the project, you can see evaporative cooling increase, which is indicative of water being converted to vapor. In the latter half of the project, you can make adjustments when you find “dead” or “cool” spots and reposition airflow to adequately deliver heat.

Velometers or Wind Meters ensure proper balance of airflow, allow you to manipulate openings to deliver more heat to wetter structure, and prevent over-pr

High-temp hygrometers give accurate readings temperatures 200F plus. Hygrometers are necessary to measure moisture removal using the GIGO(grains-in grains-out) method for calculation. Monitoring for heat drying with forced-air propane heaters, and diesel indirect-fired heaters requires you to measure the cubic feet of air entering the structure, followed by measuring the GPP of the air going in and the grains per pound exiting the structure.